Fills and Drift Eliminators

Fills

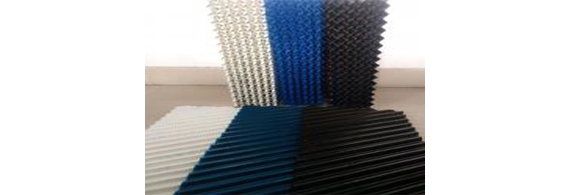

The principal of operation of cooling tower fill is to put as much water surface area in contact with as much air as possible, for the longest amount of time possible Over time, cooling tower fill can become brittle lose its it’s film surface, become fouled or perhaps the site conditions or process has changed and the original fill no longer fits the current or future cooling tower needs. Each fill has performance characteristics that allow selections to be made for various heat loads, cooling tower types, flow rates, water quality and horse power combinations. Sequana TowerServices offers a wide variety of cooling tower film fills (vertical fluted, cross corrugated, offset vertical) that can be custom selected for your cooling tower operation needs. SEQUANA can supply for your dirty water applications splash fill or splash grid fill.

Specification

| Characteristics | Units | SQ-12F | SQ-19F | SQ-27F |

|---|---|---|---|---|

| Cooling tower application | Counterflow | Counterflow | Crossflow | |

| Flute Height | Mm | 12 | 19 | 27 |

| Standarad dimensions | Mm*mm | 2400*600 | 2400*600 | 2400*600 |

| Materials | PVC | PVC | PVC | |

| Material Thickness | Mm | 20 | 25 | 35 |

| Surface area per unit volume | M2/m3 | 250 | 158 | 120 |

| Weight | Kg/m3 | 35 | 27 | 28 |

.jpg)

Drift Eliminators

In every wet cooling tower, there is a loss of water to the environment due to the evaporative cooling process. To address this, cooling tower drift eliminators must be installed.

A drift eliminator is designed to capture large water droplets caught in the air stream, and prevent the droplets and mist from escaping the cooling tower. Over time, however, the drift eliminator can wear out and become brittle, or even become clogged if no proper preventative maintenance plan is implemented.

How can we help you?

Design & Developed by sunnycirtix

.png)